Manufacturers without real-time production monitoring systems face extended downtime because problems are identified later, which leads to lost production and extra costs. Factory operators need real-time insight to optimize processes, manage inventory effectively, or forecast demand. This is where an IoT-based manufacturing production monitoring software provides real-time visibility from various touchpoints across the manufacturing process that helps manufacturers in:

- Enhancing Operational Efficiency

- Improving Quality Control

- Increasing Visibility and Transparency

- Enabling Predictive Maintenance

With over two decades of experience in developing digital factory solutions, we offer end-to-end implementation of real-time production monitoring software that connects diverse smart devices to ensure production uptime, lowering expenses and eliminating waste.

Read on to explore production monitoring systems’ key features, benefits, and use cases. Learn how it can help you monitor production performance KPIs and downtime events in real-time for enterprise-wide visibility.

What Does IoT-enabled Real-time Production Monitoring System Mean?

It refers to a system that uses IoT technology to monitor and track the status and performance of manufacturing equipment and production processes in real-time.

An IoT-based PMS (production monitoring system) leverages the connectivity and data capabilities of the connected IoT ecosystem to provide manufacturers with unprecedented visibility and control over their production processes, enabling them to improve operational efficiency, quality, and competitiveness.

How Does the IoT Production Monitoring System Work?

Here’s how it works:

Sensors and Devices Collect Real-Time Data

The software uses various sensors installed on production equipment to collect real-time data on critical parameters like:

- Machine performance

- Environmental conditions

- Product quality

- Resource usage

The gathered data is transferred to a gateway or a central controller to gather insights, identify inefficiencies, and enable better decision-making.

Data Transmission & Processing

The gathered data is transmitted to a central controller or gateway device via Wi-Fi, wireless, or Bluetooth. Initial processing and analysis are usually done at the gateway using a small microcontroller. More complex analytics involving advanced algorithms and machine learning usually take place in the cloud to provide deeper insights.

Cloud-based Analytics and Visualization

The cloud-based analytics tools process the collected data to analyze trends, detect anomalies, and monitor machine performance, production output, and worker productivity in real-time The processed data is displayed through a web-based dashboard or mobile app for easy monitoring for production managers and operators.

Optimization and Predictive Maintenance

The insights from the system can be used to suggest process improvements, schedule predictive maintenance to optimize the production process, and trigger alerts if the software identifies any bottlenecks.

What are the Key Components of IoT-based Smart Production Monitoring System?

The key components of production monitoring software work together to create a smart, connected, and data-driven production environment that enhances overall efficiency, reduces costs, and improves product quality.

- Sensors and actuators: Collect data and execute actions in the production environment.

- Connectivity infrastructure: Enables data transmission between devices and systems.

- Data processing and analytics platform: Transforms raw data into actionable insights.

- User interface/dashboard: Visualizes data and allows system interaction.

- Cloud storage and computing: Provides scalable data storage and processing capabilities.

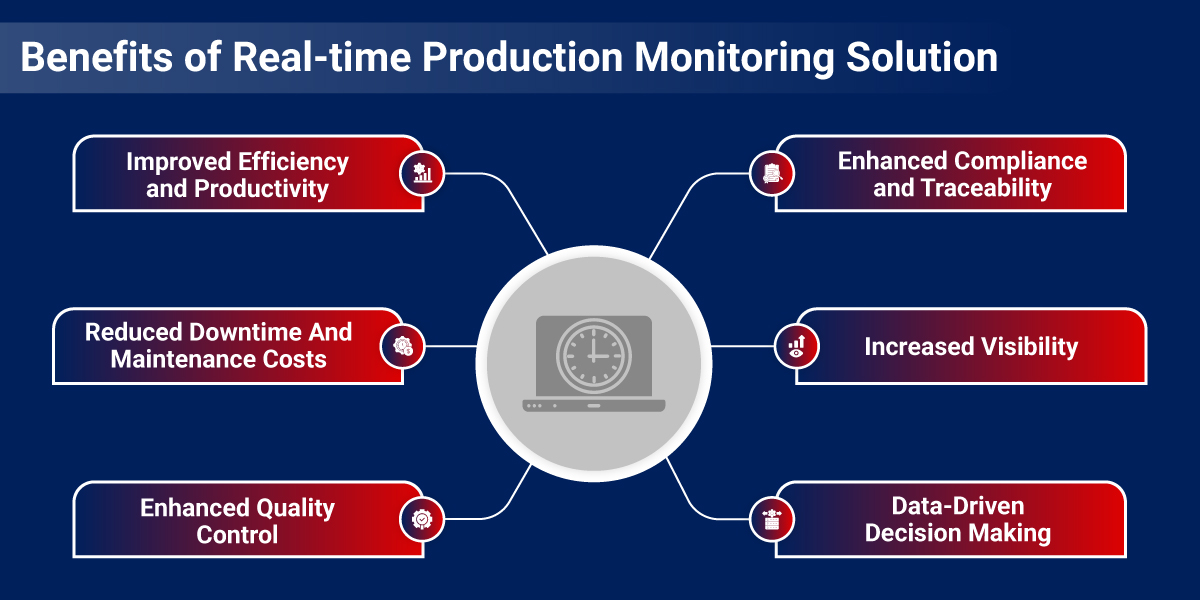

Benefits of Real-time Production Monitoring System for Manufacturers

By transforming raw sensor data into advanced analytics, a PMS offers improved visibility to maximize efficiency and reduce downtimes. Here’s how it helps unlock your factory’s hidden potential.

Improved Efficiency and Productivity

With the help of real-time monitoring software, manufacturers can continuously track key production metrics such as

- Overall equipment effectiveness (OEE)

- Production rate

- Quality rate and other metrics

The IoT-based PMS assists in quickly identifying bottlenecks, inefficiencies, or underperforming processes. As a result, production managers and supervisors can immediately adjust to optimize production flow, resource allocation, and machine utilization. This transparency allows for better decision-making and problem-solving.

Reduced Downtime And Maintenance Costs

The system comes with a predictive maintenance approach, which allows manufacturers to detect potential issues before they lead to breakdowns. It also helps in scheduling repairs during planned downtimes and reduces unexpected blockages. This will help in extending the equipment’s lifespan and reduce maintenance costs.

Enhanced Quality Control

PMS can track product quality parameters throughout production. Any variations from set standards can be immediately flagged and addressed; it will help reduce defects and waste. This leads to higher product quality, fewer returns, and increased customer satisfaction.

Enhanced Compliance and Traceability

For industries with strict regulatory requirements, real-time monitoring software can help ensure compliance by tracking and documenting every step of the production process. This improves product traceability, which is crucial for quality assurance and recall management.

Increased Visibility Into Operations

It provides a holistic view of your floor operations in real-time. This transparency offers better coordination between different departments and shifts. It also allows faster response times to issues and facilitates more accurate reporting and forecasting.

Data-Driven Decision Making

The access to accurate, real-time information about your production process allows you to take faster corrective actions across production scheduling, resource allocation, and process improvements. Over time, this can significantly improve the bottom line.

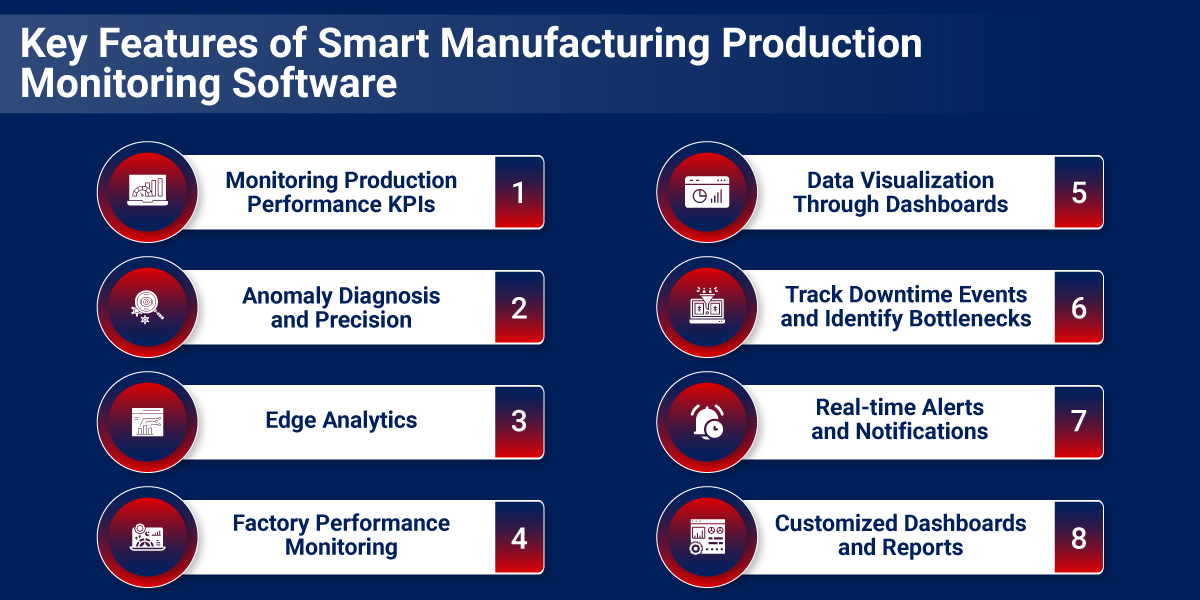

Key Features of a Smart Manufacturing Production Monitoring Software

Before selecting a PMS, you must understand the features to ensure your system remains secure, scalable, and robust in the future.

Monitoring Production Performance KPIs

- Tracking key metrics like OEE, throughput, and cycle time in real-time, together with accurate and up-to-date information, ensures instant insights into production efficiency.

- The system alerts users when performance deviates from expected targets and set KPIs.

Anomaly Diagnosis and Precision

- Advanced algorithms detect deviations from normal production patterns, enabling proactive maintenance and quality control.

- Root cause analysis tools correlate data from multiple sources to quickly identify and resolve issues.

Edge Analytics

- On-site data processing reduces latency and enables near-instantaneous decision-making in high-speed manufacturing environments.

- Local data filtering and aggregation optimize network bandwidth usage and improve overall system efficiency.

Factory Performance Monitoring and Predictive Analytics

- Real-time monitoring offers a holistic view of entire factory operations to understand interdependencies and optimize overall performance.

- The use of Machine Learning models helps forecast maintenance needs and production outcomes, thus increasing uptime and productivity.

Data Visualization Through Dashboards

- Provides intuitive, real-time visual representations of production data, including live floor maps, trend charts, and performance gauges.

- Customizable charts and graphs allow users to create visual representations that best suit their specific needs.

Track Downtime Events and Identify Bottlenecks

- Automatic logging and categorization of downtime events allows for detailed analysis of production interruptions.

- Advanced analytics tools to pinpoint recurring issues and production constraints, enabling targeted improvement efforts.

Real-time Alerts and Notifications for Critical Events

- Instant multi-channel notifications (email, SMS, mobile app) inform relevant personnel of urgent issues.

- The software ranks issues based on severity, so critical issues receive immediate attention.

Customizable Dashboards and Reports

- User-specific views tailored to different roles provide relevant information for each job function.

- The drag-and-drop interface allows for easy creation and modification of dashboards without advanced technical skills.

To help you achieve maximum efficiency and deliver tangible business value, we have the capabilities to build and integrate IoT-based manufacturing production monitoring software tailored to your business needs. From sensor integration to cloud-based analytics, we handle every aspect of your IoT ecosystem with our end-to-end capabilities.

Use-Cases of IoT-Based Production Monitoring Software

Here are some key use cases for IoT-based production monitoring software in manufacturing:

Real-time Equipment Monitoring

The software can continuously track manufacturing equipment’s status, performance, and health using IoT sensors and devices. The collected data is then analyzed in real-time to provide insights into machine performance and potential issues.

This results in:

- Reduces downtime through early detection of equipment problems

- Improves overall equipment effectiveness (OEE)

- Enhances predictive maintenance capabilities

- Better resource allocation and capacity planning

Example:

Vibration monitoring sensors on a motor can help identify defects and potential failures, allowing maintenance to be scheduled before a breakdown occurs.

Energy Management

PMS monitors energy consumption across the production facility, providing detailed insights into energy usage patterns and opportunities for optimization.

This results in:

- Reduces energy costs

- Improves environmental sustainability

- Better compliance with energy regulations

- Identifies equipment inefficiencies

Example:

IoT sensors can identify areas of compressed air leakage, which leads to significant cost savings and efficiency improvements. It is a common source of energy waste in manufacturing facilities.

Production Planning and Scheduling

The system collects real-time data on production rates, machine availability, and order status, enabling more accurate and dynamic production planning and scheduling.

This results in:

- Improves production efficiency and throughput

- Reduces lead times and work-in-progress inventory

- Better resource utilization

- Enhances the ability to respond to changes in demand or production conditions

Example:

An IoT-enabled production monitoring software can automatically adjust production schedules based on up-to-date data about machine availability and order priorities.

Safety and Compliance

IoT production monitoring devices track various safety parameters such as air quality, noise levels, and equipment operation. They can also track worker locations and activities to ensure compliance with safety procedures.

This results in:

- Reduces workplace accidents and injuries

- Improves regulatory compliance

- Enhances ability to investigate and prevent safety incidents

- Better training and safety procedure development based on data insights

Example:

A wearable IoT device can send a notification when a worker is in a risky area or high-risk environment to minimize accidents.

Choose Us to Build and Deploy IoT-based Manufacturing Production Tracking Software

With over two decades of experience serving a global clientele, we have a proven track record in integrating IoT systems for the manufacturing industry, ensuring solutions tailored to your business needs. With a deep understanding of the complexities involved in ERP, MES, and IoT projects, we empower manufacturers with our IoT Application Development Services.

Our expert team of software developers can help you develop and integrate state-of-the-art IoT production monitoring software solution that drives enhanced efficiency and productivity improvements through real-time production visibility to increase the profitability of your factories and production processes.

With our IoT consulting services, we have partnered with big and small businesses across diverse sectors, including Automotive, Energy, and pharmaceuticals, in analyzing their specific industrial needs, helping in prototyping IoT solutions and planning implementation roadmaps.

Frequently Asked Questions

Q: What are the data collection methods for the production monitoring system?

A: Below mentioned are the data collection methods:

- Sensors and IoT devices: Collect real-time data on machine performance, environmental conditions, and product flow.

- Machine connectivity (PLC integration): Directly connects to machine controllers to gather operational data and status information.

- Manual data entry: It enables operators to input data that are not automatically captured, like quality checks or batch information.

- Barcode/RFID scanning: Tracks movement of materials, work-in-progress, and finished goods throughout production.

- Vision systems: It utilizes computer vision technologies, which include cameras and image processing, to monitor product quality and assembly processes.

Q: What types of data can be monitored using these systems?

A: Here are the types of data monitored using real-time production monitoring system:

- Production quantities

- Cycle times

- Machine uptime/downtime

- Quality metrics

- Energy consumption

- Material usage

Q: How does the production monitoring system integrate with existing manufacturing infrastructure?

A: It integrates with present manufacturing infrastructure through:

- API connections to ERP/MES systems for seamless data exchange

- Direct machine connectivity, often via PLC integration

- Cloud-based solutions that require minimal on-site installation

- Customizable interfaces that can be tailored to match current workflows and processes

These methods allow the monitoring system to work alongside and enhance existing equipment and software without major disruptions to operations.

Q: How can SMEs benefit from manufacturing production tracking software?

A: Here are some benefits of manufacturing production tracking software for SMEs:

- Increased visibility into operations

- Improved decision-making

- Cost reduction through efficiency gains

- Enhanced quality control

- Easier compliance and reporting

Additionally, Rishabh Software offers custom manufacturing software solutions to enhance your production operational efficiency and automate your business processes by leveraging next-gen technologies.

Q: How to improve production monitoring?

A: To improve production monitoring:

- Implement real-time data collection for up-to-date insights

- Use data visualization tools to make information more accessible

- Set up automated alerts for quick response to issues

- Train staff thoroughly on system use and data interpretation

- Regularly review and optimize Key Performance Indicators (KPIs)

- Integrate monitoring across all production stages

- Use predictive analytics to anticipate potential problems

- Ensure mobile accessibility for monitoring on-the-go

These steps help enhance visibility, responsiveness, and overall efficiency in production processes.

Q: How to track production in manufacturing?

A: To track production in manufacturing:

- Implement a Manufacturing Execution System (MES) for comprehensive monitoring

- Use barcode or RFID tracking to follow materials and products

- Employ digital work instructions to standardize processes

- Utilize production dashboards for real-time visibility

- Implement regular reporting and analysis of production data

- Install IoT sensors on key equipment for automated data collection

- Use machine vision systems for quality control tracking

- Implement a centralized data management system for all production metrics

30 Min

30 Min