Staying competitive in the Industry 4.0 era requires more than just efficient production. Factories must also focus on quality control, minimal downtime, and cost optimization.

Traditional Manufacturing Execution System (MES), although efficient at streamlining production on the shop floor, is alone isn’t enough to achieve a smarter, more connected, and more efficient production environment.

That is where IoT-enabled MES in manufacturing industry comes into the picture. As factories embrace digital transformation to keep up with the demand for quick, top-quality, innovative products, the integration of IoT and MES enables enhanced real-time visibility and autonomous operations. This game-changing duo is transforming the way products are manufactured, monitored, and modified. Let’s understand the role of IoT enabled MES in manufacturing industry and how you can leverage this powerful tool to achieve total efficiency.

The Role of IoT-Enabled MES in Manufacturing Industry

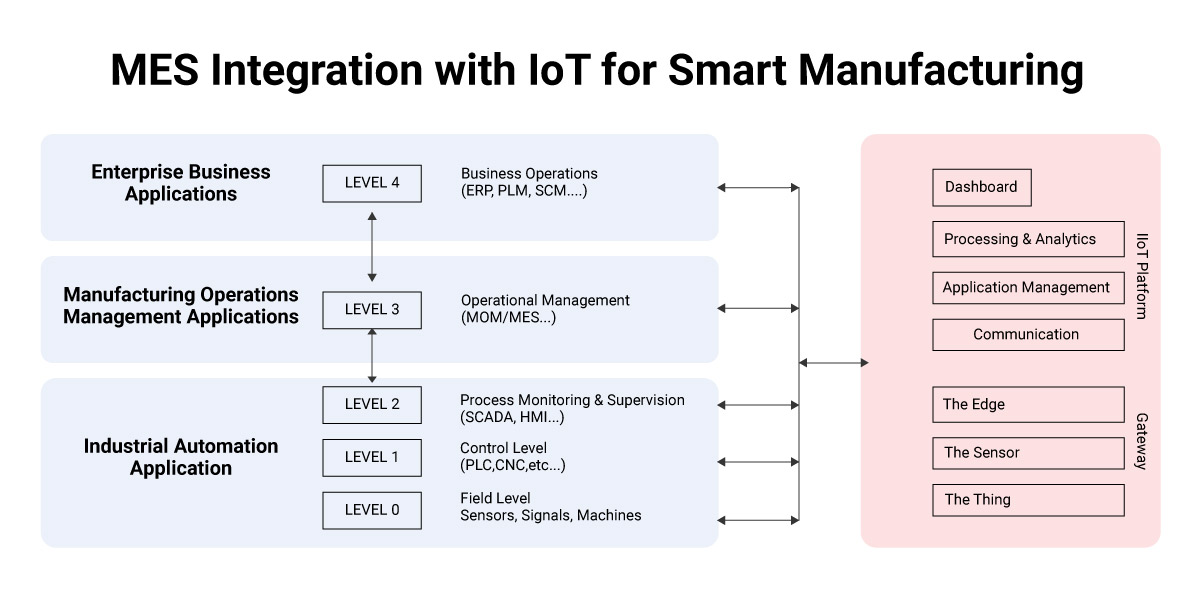

Combining IoT and MES allows manufacturers to achieve significant improvement in efficiency, productivity, and quality. Implementing IoT-enabled Manufacturing Execution System for digital factory helps leverage the real-time connectivity of IoT and the process control and optimization capabilities of MES.

Enhanced Data Collection and Monitoring

MES complements the IoT by providing details on customers, orders, products, receipts, bills of materials, and more, completing the context for data analysis and root cause determination. The IoT-enabled manufacturing execution system for digital factory then processes and analyzes this data to generate actionable insights that enable faster and better decision-making at every level.

Increased Real-Time Visibility

This integration offers a 360-degree view of production processes. Factory managers can track materials and products, monitor equipment performance, and implement IoT predictive maintenance strategies for operational success.

Increased Agility

When integrated with IoT, MES enables you to react to rapid changes on the shop floor, analyze situations, and respond with new changes. It communicates these changes to the systems, machines, and people involved. It ensures accuracy, error-proofing, and enforcement in manufacturing operations, working in tandem with the manufacturing team to determine and execute necessary changes.

Unlock Smart Manufacturing

MES uses the data from ERP systems to provide additional context with orders, materials, batches, and people. It then uses data collected from IoT sensors on machines to monitor and optimize production in real-time. The relationship between the IoT and MES is symbiotic. It also enables factory owners and operators to leverage smart technologies like AI, machine learning, and edge computing for smart manufacturing.

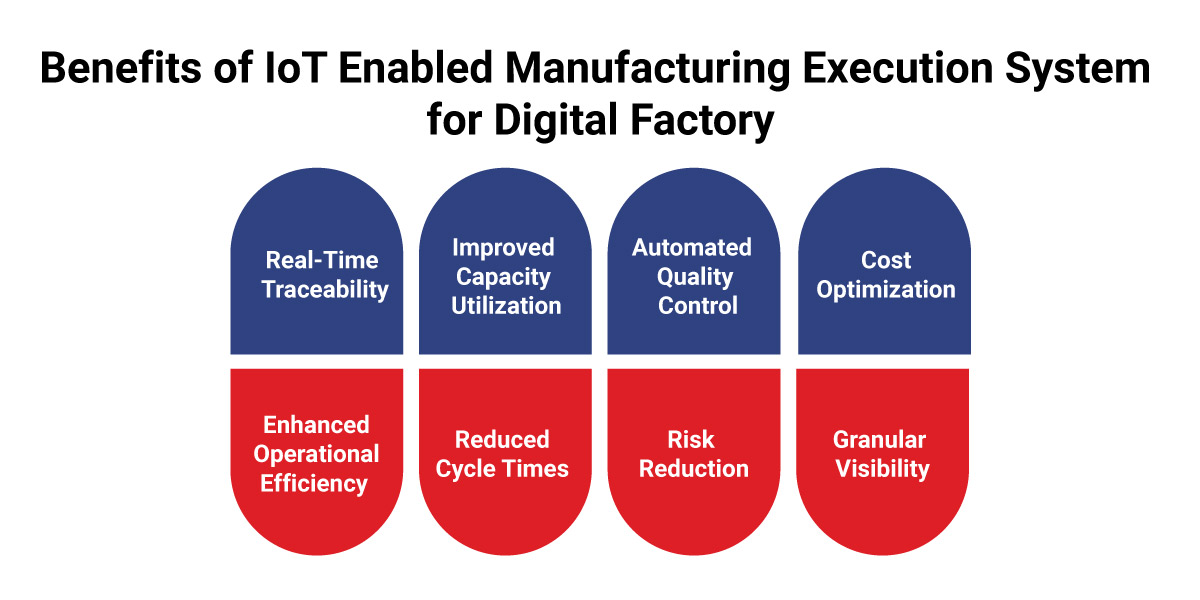

The Benefits of Integrating Manufacturing Execution System with IoT Technology

MES integration with IoT is not merely a technological upgrade; it is a strategic move that unlocks undeniable advantages by modernizing the operational dynamics of smart factories. Major advantages of MES Integration with IoT are:

Real-Time Traceability: Sensors embedded throughout the production line gather and infuse data into the MES. This helps trace every moment of the products seamlessly across the entire supply chain, capturing material genealogy, processes, equipment usage, and quality data in real-time.

Enhanced Operational Efficiency: Uses real-time data collection from manufacturing equipment, metrology tools, and IoT sensors to drive root-cause analysis in case of recalls to reduce defects.

Reduced Cycle Times: Optimizes resource allocation and equipment uptime for improved on-time delivery by providing real-time data and insights into the production process.

Improved Capacity Utilization: Leverages data from yield, equipment uptime, and machine speed to enhance Overall Equipment Effectiveness (OEE), leading to increased production capacity.

Risk Reduction: IoT-enabled MES ensures the use of correct raw materials, tools, and equipment parameters, thus minimizing the risk of poor-quality incidents.

Automated Quality Control: Streamlines quality assurance through automated checks throughout production processes. This translates into reduced errors, thus increasing production yields, and eliminating costly rework.

Granular Visibility: Integrate MES with ERP for real-time visibility at all management levels. It helps stay on top of shop-floor operations and track financial impact in real time.

Cost Optimization: When you implement domain-specific software you don’t need different software licenses. This also eliminates the hassles of periodic upgrades, costs of integration, and the need for customization.

Challenges of Implementing IoT-Enabled MES in Manufacturing Industry

When integrating an MES with IoT technologies, organizations often face hurdles. Listed below are common challenges along with effective strategies for a smoother and more successful implementation process:

Data Integration Dilemmas: Integrating IoT-enabled MES with existing systems like ERP, PLM, or SCM can be downright daunting. Seamless data exchange demands extensive customization, data mapping, and integration efforts. Inaccuracies during integration can compromise decision-making.

Complex Implementation: Implementing custom IoT-enabled manufacturing execution software for a digital factory can be a technically complex initiative. It calls for careful planning and seamless integration with existing hardware and software systems. As a result, there is an inherent risk of delays and the possibility of budget overruns.

Change Management Challenges: The introduction of an IoT-enabled manufacturing execution system often involves restructuring business processes and workflows. Effective change management enabled with training is key to ensuring a smooth transition and user adoption.

Data Security Concerns: The increased connectivity and data exchange that results from MES integration with IoT makes the organization susceptible to cyber-attacks and data breaches. Securing this data from unauthorized access and cyber threats is critical. You must therefore ensure robust encryption and access controls to mitigate risks.

Strategies for Successful Implementation of IoT-Enabled Smart Manufacturing Execution System

Effective implementation of IoT-enabled MES requires careful planning and strategy to drive operational excellence in your manufacturing environment. Here are key strategies to consider:

- Precisely outline your IoT integration goals, focusing on impactful areas such as predictive maintenance and quality control.

- Evaluate the readiness of your current ERP, SCM, and MES systems for seamless IoT integration. You can seek external assistance to plan necessary upgrades or modifications.

- Choose compatible IoT devices that align with your manufacturing needs and enable seamless integration with advanced planning systems.

- Devise a data integration strategy that ensures consistent data flow between IoT devices and planning systems.

- Implement security measures that include robust encryption and access controls to protect your IoT devices and data.

- Conduct a controlled pilot project to assess performance and collect feedback for optimization.

- After a successful pilot, implement IoT integration across the facility along with comprehensive training and support.

- Regularly monitor and evaluate IoT integration, making adjustments to maximize its value in advanced planning.

How You Can Achieve Manufacturing Excellence with Our IoT-Enabled MES Implementation and Integration Services?

Kick-start your MES transformation initiatives with Rishabh Software, where we employ a process-led, turnkey approach that leverages our technology prowess and domain-specific experience. Here’s what you get when you partner with us:

Expertise in MES Transformation: We bring industry-specific MES best practices to help you optimize end-to-end digital transformation. Our vetted cross-industry experience makes us an ideal partner for implementing custom MES integration with IoT and support services. Our MES services include IoT integration and IoT software development services.

We can tailor manufacturing execution solutions to your unique needs and help you build custom manufacturing software solutions for your digital factory, ensuring a perfect fit for your operations.

Legacy System Upgrades: Maximize the returns on your technology investments by modernizing legacy systems and implementing new software platforms for enhanced production capacity.

Plant and Process Visualization Dashboards: We empower your business, operations, and manufacturing units with IoT-powered solutions that integrate data analytics. Our IoT dashboards simplify complex operations, providing clarity for effective monitoring and maximizing production opportunities.

End-to-End Strategy and Execution: From envisioning and designing to testing, implementing, and validating process operations, Rishabh Software manages the complete lifecycle of your MES transformation.

Data-Driven Insights: Our capabilities extend to data extraction and aggregation, extracting valuable insights from manufacturing line equipment data for continuous process and performance improvements.

Discover how we helped an Asian manufacturer of fluid control systems optimize their operations with an IoT-powered solution for fluid management and advanced data analytics.

Frequently Asked Questions

Q: What is IoT-enabled manufacturing execution software and how does it differ from a traditional MES?

A: A traditional MES is mainly designed to monitor, manage, and optimize production processes. An IoT-enabled manufacturing execution software for digital factory enhances this capability by integrating sensor data from connected devices to enable real-time analysis for informed decision-making.

Q: What are the key features to look for in a custom IoT-enabled manufacturing execution solution for digital factory?

A: Here are the key features to consider:

- Connectivity: Seamless MES integration with IoT

- Scalability: Easily adaptable to changing factory needs.

- Security: Robust measures to protect sensitive data.

- Real-time dashboards:Keeps you on top of maintenance schedules to prevent repairs and breakdowns.

- Quality control:Tracks every product and process to ensure top-notch quality.

- Automation & AI: allows you to work at peak efficiency with a self-tuning engine.

Q: List Real-world examples of MES Systems across industries

A: Notable examples across business verticals include:

Manufacturing:

- Boeing: Uses IoT sensors to track parts and tools, reducing assembly time and errors, and improving overall efficiency.

- GE: Connects industrial machines to the cloud for real-time data analysis, enabling predictive maintenance and asset optimization.

Automotive:

- Tesla: Leverages IoT to collect data from vehicles, enabling over-the-air software updates, remote diagnostics, and personalized features.

- BMW: Connects production lines with IoT sensors to track parts, monitor quality, and optimize production processes.

Pharmaceutical:

- Pfizer: Uses IoT to track temperature and humidity in drug storage facilities, ensuring compliance with regulations and preventing product spoilage.

- Novartis: Implemented IoT-enabled MES to track and trace drugs throughout the supply chain, preventing counterfeiting and ensuring patient safety.

Agriculture:

- John Deere: Uses IoT-enabled tractors and combines to collect data on soil conditions, crop health, and yield, enabling precision farming practices.

30 Min

30 Min