A new report from Siemens[1] suggests that unplanned downtime costs Fortune Global 500 companies 11% of their yearly turnover – almost $1.5tn.

One of the most important things will be to reduce the unplanned downtime of the factory, and an effective way to achieve this is by using IoT in predictive maintenance. By integrating connected sensors and AI, companies can identify asset conditions and performance patterns, prevent failures, and accurately assess maintenance needs. With 24/7 monitoring, real-time alerts, and root cause analysis, organizations can extend the life of machines and components, eliminate unexpected downtime, lower service costs, and increase production output.

The use of IoT-based predictive maintenance is, thus, a necessity for industries to cut unplanned downtime and thrive in the Industry 4.0 era! If you want to harness the potential of IoT in predictive maintenance to solve your business challenges, then this blog is for you. Here’s what we will cover:

What is the Role of IoT in Predictive Maintenance?

Have you ever questioned the need for an Industrial IoT (IIoT) solution when SCADA (supervisory control and data acquisition) is already an architecture that oversees maintenance activities?

Efficient predictive maintenance requires more than SCADA’s control system architecture to anticipate failures and optimize maintenance actions. It demands sophisticated algorithms and the ability to process vast data volumes, which localized SCADA implementation alone cannot achieve.

This is where IoT and machine learning can offer cloud connectivity and data transmission to enrich SCADA data to generate insights and recommendations. The architecture seamlessly collects machine data through connected sensors and wirelessly transmits it to cloud-based storage in real-time. Driven by IoT, a smart factory app can store terabytes of data environment data and status data and run machine-learning algorithms on parallel computers to forecast hazards and predict equipment breakdown.

Maintenance teams can extract and analyze these data sets, utilizing AI and Big Data algorithms to derive actionable insights and recommendations from vast information.

Data-tracking IoT devices ensure manufacturers can predict potential failures or outages. This allows them to respond swiftly to equipment issues, thus enhancing operational efficiency.

The Evolution of Predictive Maintenance

There are broadly three types of maintenance strategies: Reactive, Preventive, and Predictive. When mission-critical machinery breaks down, and manufacturers get it fixed – it’s called reactive maintenance. Similarly, it is called preventive maintenance when you maintain your machines on a set schedule. However, the preventive approach may be inefficient as the device can break down before the scheduled maintenance service. So, with the latest technological advancements, industries got smarter and started using vibration monitors and ultrasonic devices for predictive maintenance. But the traditional predictive maintenance approach was exhausting and needed frequent onsite visits, data analysis, and manual recordings.

Here’s when predictive maintenance using IoT comes into the picture!

IoT-based predictive maintenance solution enables organizations to move from condition-based monitoring to a proactive and data-driven approach by continuously assessing the equipment’s condition. It uses IoT tools like vibration analysis, ultrasonic analysis, infrared analysis, and motor circuit analysis, which constantly monitors and analyzes the asset’s performance and condition.

By leveraging real-time data and predictive analytics, companies can reduce the cost of maintaining a machine and still increase their system’s uptime.

How Does IoT Predictive Maintenance Work?

IoT-based predictive maintenance utilizes sensors, connectivity, and data analytics to optimize maintenance activities. Let’s understand how IoT in predictive maintenance works:

Sensor Deployment for Data Acquisition and Transmission

The implementation starts with wired or wireless IoT sensors acquiring data like vibration, temperature, or noise levels that are an indicator of the condition of the equipment. The data is then filtered and processed using field or cloud gateways to be sent to the cloud.

Data Storage and Processing

Raw data is rarely meaningful by itself! Therefore, data processing converts the raw data into meaningful information. This processing is usually centralized in a data center or a cloud server. Thus, the raw data of readings from multiple sensors go through a streaming data processor to allow a continuous flow into a data lake that stores data gathered by sensors. Here the data is structured, cleansed, and analyzed with machine learning algorithms to identify data patterns and correlations in data sets. Once the data is processed and ready to be acted on, it is stored for future analysis because long-term analysis is necessary to improve the ML algorithms and predictive models as well as to identify and resolve systemic issues.

Presenting the Data

The next step involves presenting actionable data and reliable estimates on when maintenance will be needed on a specific industrial asset in an intuitive visual interface. The best IoT predictive maintenance systems connect these insights with supporting data behind them that can be easily examined by operators who want to dig into the details. The more advanced systems take the individual sensor analysis and combine it with a knowledge database using AI and make clear recommendations on what actions need to be taken or even create a service ticket for the operator to review.

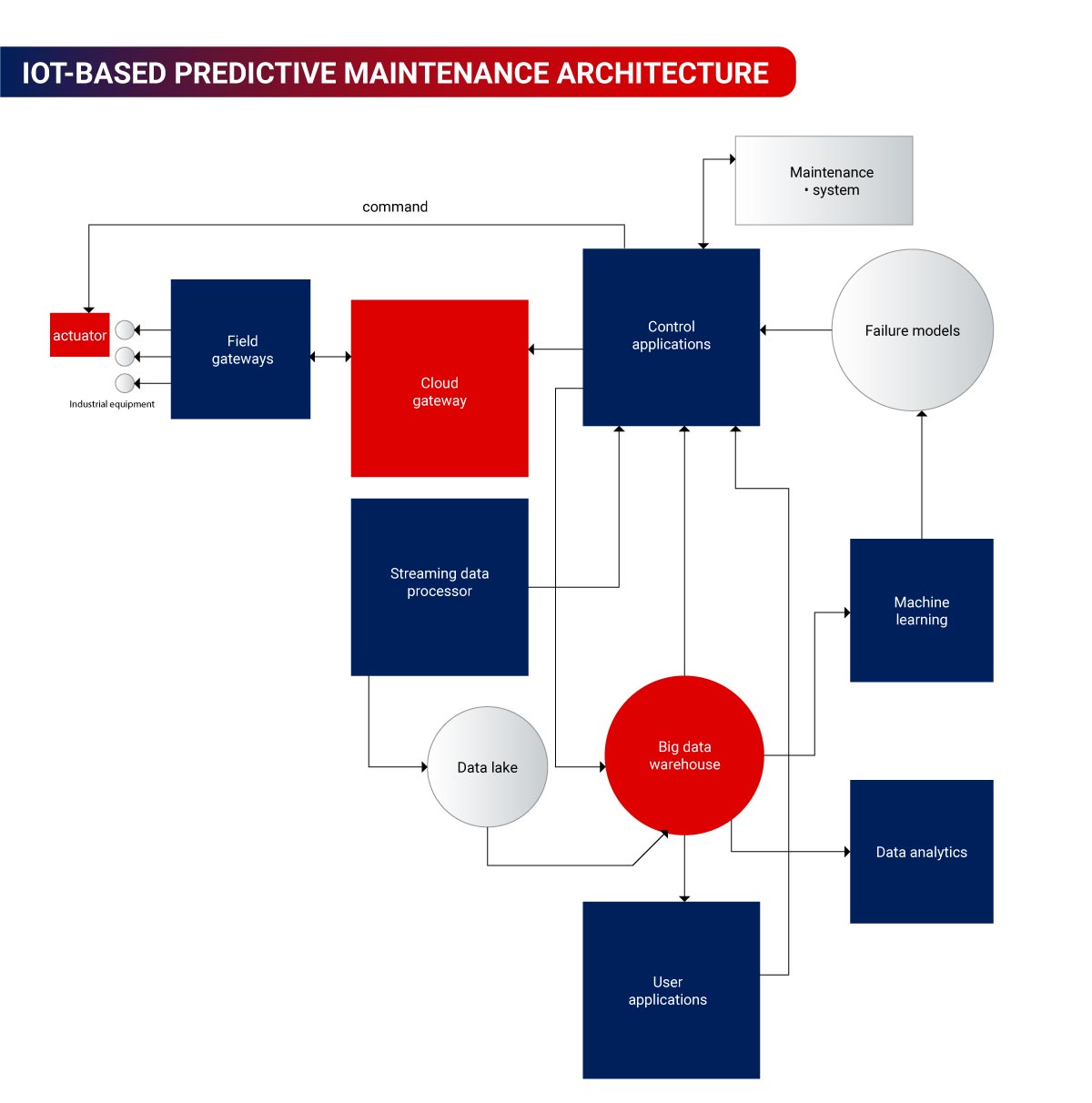

IoT-Based Predictive Maintenance Architecture

IoT in predictive maintenance harnesses the power of real-time data gathered from sensors deployed across devices, systems, assets, and locations. Manufacturers can revolutionize their maintenance practices by embracing an IoT based predictive maintenance platform encompassing these vital components.

Key Components of IoT-based Predictive Maintenance

Sensors:

Predictive maintenance relies heavily on sensors for fault detection, failure detection, and Computerized Maintenance Management System (CMMS) integration. They capture the temperature, vibration pattern, and pressure or other relevant metrics of the asset, such as rotating equipment like pumps, motors, gearboxes, bearings, etc. These sensors connect to the CMMS solution to share the raw data they capture through a gateway. Maintenance teams use six popular types of sensors: vibration, gas, humidity, temperature, security, and pressure sensors.

IoT Gateways:

An IoT gateway is a hardware or software component that connects sensors to the cloud to transmit the gathered data to centered data storage, where the data is filtered and pre-processed. IoT Edge field gateways and protocol or cloud gateways are two major gateways. While field gateways are located close to the device on-premises, cloud gateways host device instances to enable communication between devices and the cloud.

Cloud Infrastructure for Data Storage:

Cloud infrastructure refers to the centralized data location where all the raw data captured by sensors is gathered and stored in a data lake or warehouse. It also stores business data from disparate IT systems.

Predictive Maintenance Platform:

This platform serves as a conduit, delivering the streamed data sets to maintenance teams and repair engineers in real time. It also incorporates user-defined thresholds to notify stakeholders promptly when a machine operates outside acceptable parameters. Additionally, the platform generates regular reports for further analysis and decision-making.

Data Processing and Analysis:

Once the encrypted data collected from sensors and gateways reaches the cloud, it is processed and analyzed with powerful algorithms to uncover hidden patterns, detect anomalies, and highlight potential failures or impending issues.

Predictive Models:

Based on the insights generated, predictive models are employed to spot trends and patterns that human eyes might miss. This helps you accurately forecast failure probabilities and estimate remaining service life. Predictive models can also recommend optimal maintenance schedules. It’s like having a virtual maintenance expert by your side, whispering the best course of action in your ear.

User Applications:

The predictions and analyses generated by the predictive models are seamlessly delivered to end-users via an intuitive and user-friendly application. This works like a dashboard sending you real-time alerts and instant notifications with comprehensive reports. These applications empower your maintenance personnel with all the information they need to take proactive steps and prevent unplanned downtime or costly equipment failures. No more relying on guesswork or reactive measures!

The Implementation Stages of IoT-Based Predictive Maintenance

IoT encompasses a network of interconnected devices and sensors that enable seamless data collection and exchange over the Internet. On the other hand, predictive maintenance in IoT harnesses data and analytics to anticipate equipment failures or maintenance requirements before they transpire. With this understanding, let’s go through the vital stages of implementing predictive maintenance in industrial organizations:

Study Equipment:

Not all machines in the factory would need predictive maintenance. Therefore, assessing and prioritizing only those that significantly impact your operations or incur high costs when they malfunction is important.

The implementation typically starts with assessing and specifying only those machinery needing predictive maintenance. Usually, companies consider maintenance costs to identify the most expensive equipment. Thus, to identify which equipment will need IoT predictive maintenance, you should analyze the cost of unplanned downtime if the machine malfunctions.

Choose the Right Software Tools:

Predictive maintenance tools broadly fall under IoT sensors, analytical and monitoring tools, and scheduling tools to carry out maintenance activities. You must choose the right software tools that align with your industrial domain. Investing in the right IoT predictive maintenance tools, such as Azure IoT Hub, AWS IoT Core, IBM Maximo, or others, to effectively implement predictive maintenance is crucial.

Consult a Tech Partner:

You need an experienced development partner to help you choose the right set of tools to integrate real-time data. Therefore, a vetted IoT application development company can provide valuable insights and guidance to ensure your organization’s successful implementation of predictive maintenance.

Challenges of Implementing Predictive Maintenance with IoT

You should be aware of a few potential pitfalls when implementing IoT-based predictive maintenance. These include:

Huge Upfront Investment:

There is a significant cost involved in implementing IoT solutions; however, the benefits of this long-term investment will undoubtedly provide the desired ROI.

Organizational Restructuring:

When integrating IoT-based predictive maintenance, aligning your working processes is very important. Fostering the right collaboration between the maintenance and analytical areas will help ensure smooth communication and quick service delivery.

Skill and Knowledge Gap:

Implementing IoT in predictive maintenance requires a team with hands-on IoT and data science knowledge. Here you must ensure that your in-house team is bridging this gap by upskilling with the right training and resources.

Cybersecurity Measures:

Safeguarding confidential data in the IoT network and cloud calls for strict adherence to a series of protocols, best practices, and technologies designed to ensure your data’s availability, integrity, and confidentiality. So, you need to take those extra steps to secure your IoT ecosystem and valuable business information against unauthorized access.

Scalability:

To achieve scalability with IoT across multiple assets, your company’s IT infrastructure, data management systems, and analytics capabilities should be able to handle the increasing data volume and the growing complexity of predictive models.

Regulatory and Compliance Considerations:

Organizations must strictly adhere to relevant regulations and industry standards while implementing IoT systems in certain industries like healthcare, hospitality, and manufacturing. Ensuring compliance will ensure your operations align with the industry’s practices and keep everything running smoothly.

With over two decades of custom software development experience, our proficiency spans all preferred technologies enabling IoT Connectivity for Predictive Maintenance.

Our cross-functional team at Rishabh Software can help you overcome these challenges when implementing IoT predictive maintenance solutions using the latest tech stack, best industry practices, and specialized skills. Our developers are well-versed in utilizing supportive frameworks and languages like Node.js, Python, Xamarin, Flutter, and more.

We excel in protocols and standards such as Beacon, Modbus, BLE, TCP/IP & UDP, and more. We leverage renowned IoT platforms like Azure IoT Hub, AWS IoT, NodeMCU, Beacons, and ESP 32. Additionally, we integrate an extensive range of sensors, covering Temperature, Humidity, Proximity, Pressure, Motion & Velocity, Accelerometers, Optical, Light, Magnetic, Water Quality, Smoke, Chemical, Infrared, Flow & Gas, Acoustics & Noise.

Use Cases of IoT Predictive Maintenance Across Industries

Manufacturing

As digital transformation becomes a top priority in the Industry 4.0 era, global manufacturers are adopting IoT in predictive maintenance to leverage AI and machine learning to transform traditional manufacturing plants into smart factories. It enables the manufacturer or producer to predict when key revenue-generating equipment will likely stop functioning. This allows them to make accurate predictions and schedule the optimum time for maintenance, thus significantly reducing or avoiding unplanned downtime and reducing operational overheads.

If you are interested in exploring how IIoT transforms traditional factories into smart spaces to digitize every part of business, please check out our informative piece of content on IoT in manufacturing.

Pharmaceutical

Did you know that a major part of drug shortages[2] is caused due to manufacturing issues related to quality and production issues? Optimal equipment performance and maintenance are vital to drug quality and speed to market. Unplanned downtime with no prior warning on failures can cause significant disruptions in drug supply chains, further affecting drug product quality.

Conventional scheduled maintenance, such as preventive maintenance, is a common practice to keep equipment functional and avoid failures. However, these have significant challenges. IoT in Predictive maintenance leverages AI and machine learning to ensure operational excellence. This is also in line with ISPE Pharma 4.0 initiative[3] that is that encourages the adoption of digital strategies in pharmaceutical manufacturing. It helps predict impending failures and enable.

Utility Companies

Utility companies must run their critical power assets safely and reliably with quality and competitive costs. But unplanned breakdowns and equipment failures result in high costs, can lead to power outages, and pose a risk to public safety. Predictive maintenance enables power and utility companies to monitor equipment performance in real-time and plan maintenance activities ahead of time, reducing the likelihood of equipment failures and ensuring that critical assets remain operational. By leveraging advanced data analytics and machine learning capabilities, utility companies can detect potential failures early on, reduce unplanned downtime, optimize asset performance, improve resource utilization, and reduce maintenance costs.

Transportation

According to American Trucking Association[4], Fleets are weathering the impact of aging trucks and higher parts prices. Fleet businesses must operate at peak efficiency and high utilization for good ROI, so improving fleet uptime and reducing maintenance costs is essential.

By embracing IoT for predictive maintenance, Fleet companies use AI to help detect issues and prioritize vehicle repairs before they escalate into a significant problem. It uses real-time sensor data to detect anomalies with your fleet and take swift early action. With alert notifications on battery life, fuel trim, axles, brakes, tires, and engines before any symptoms even show, fleet companies can reduce vehicle downtime, avoid breakdowns, accidents, and lower repair costs.

Railways

Imagine high-speed trains operating at 200 miles/hr, sending over 2000 signals/sec for processing for predictive maintenance.

IoT in predictive maintenance leverages big data, advanced analytics, and machine learning models for real-time sharing of information using sensors, monitoring changes in the equipment’s state of health and detecting anomalies or signs of deterioration before the developing issue takes a train or an entire portion of the railway out of service. By monitoring sensors in real-time, the operators can predict the failure of parts or machinery days in advance and schedule timely maintenance. The insights from the data can help improve the train’s safety, reliability, and availability. It ensures a leap in operational efficiency by reducing the number of failures and unplanned maintenance.

Real-world IoT Predictive Maintenance Examples

IoT in predictive maintenance has the potential to transform industries, ensuring smooth operations, increased efficiency, and significant cost savings. Here’s how:

- Sandvik: A leading tooling manufacturer created sensorized cutting equipment. It leverages the combined potential of data collection, streaming analytics, and machine learning to revolutionize its tool bit maintenance. Engineers are now notified in real-time when maintenance is needed or failure is imminent, resulting in no unexpected breakdowns and seamless production!

- ABB: The prominent engineering group has developed a groundbreaking predictive maintenance solution for critical motor and drive applications. The IoT PM solution analyzes vibrations to predict bearing failures and identifies voltage and power anomalies as indicators of potential short circuits. With this knowledge at their fingertips, they can take proactive measures to prevent costly disruptions.

To explore more use cases across industries, do check out our comprehensive blog post on Enterprise IoT, also known as Industrial IoT (IIoT).

Benefits of IoT-based Predictive Maintenance

Implementing predictive maintenance in IoT offers organizations a multitude of advantages, including:

- Prevent Breakdowns and Downtime: IoT sensors constantly monitor the equipment to check for any anomalies or defects and instantly send a notification every time a piece of equipment breaks down or a component fails. This allows the maintenance team to be more proactive in identifying when equipment is likely to fail. This allows the organization to address the issue and avoid unplanned downtime and costly repairs.

- Improved Workplace Safety: Equipment breakdown can threaten employees’ health or destroy facility infrastructure in certain work environments. IoT predictive maintenance systems have sensors to detect failure-indicating signals, ensuring minor issues do not escalate to catastrophic failures.

- Increased Equipment Lifespan: Predictive maintenance gives companies a comprehensive view of equipment health to prioritize and schedule repairs, effectively enhancing equipment lifespan.

- Lower Maintenance Cost: With real-time access to metrics on machine health, usage, and risk areas of the equipment, organizations can address the root cause earlier on. This helps prevent wear and tear, resulting in fewer unnecessary repairs, longer equipment lifespan, and reduced maintenance costs.

- Enhanced Production: Since IoT predictive maintenance systems detect errors in real-time, it ensures that downtime does not hamper production. Maintenance teams can thus run at peak efficiency through proactive scheduled repairs, ensuring that factors that usually affect overall productivity, such as downtime, costs, and safety issues, no longer hamper businesses as much as before.

How Rishabh Can Help You Get Started with IoT-enabled Predictive Maintenance

Our team will work closely with you to understand your specific maintenance challenges and goals. We will also help you identify areas where IoT based predictive maintenance can bring the most value to your business.

Based on the assessment, we will develop a tailored IoT predictive maintenance solution that aligns with your unique requirements. Our experienced IoT developers will design and deploy sensors, data communication systems, central data storage, predictive maintenance platforms, and predictive analytics tools to enable real-time monitoring and predictive insights.

We will also ensure seamless integration of IoT devices, sensors, and existing systems within your infrastructure. Leveraging machine learning algorithms and advanced analytics, we will develop models that can analyze the collected data and identify patterns, anomalies, and potential equipment failures. This will empower you to make data-driven decisions, optimize maintenance schedules, and minimize costly downtime.

Let’s explore how we helped a leading manufacturer of fluid control systems optimize its operations and drive business growth through our expertise in IoT app development.

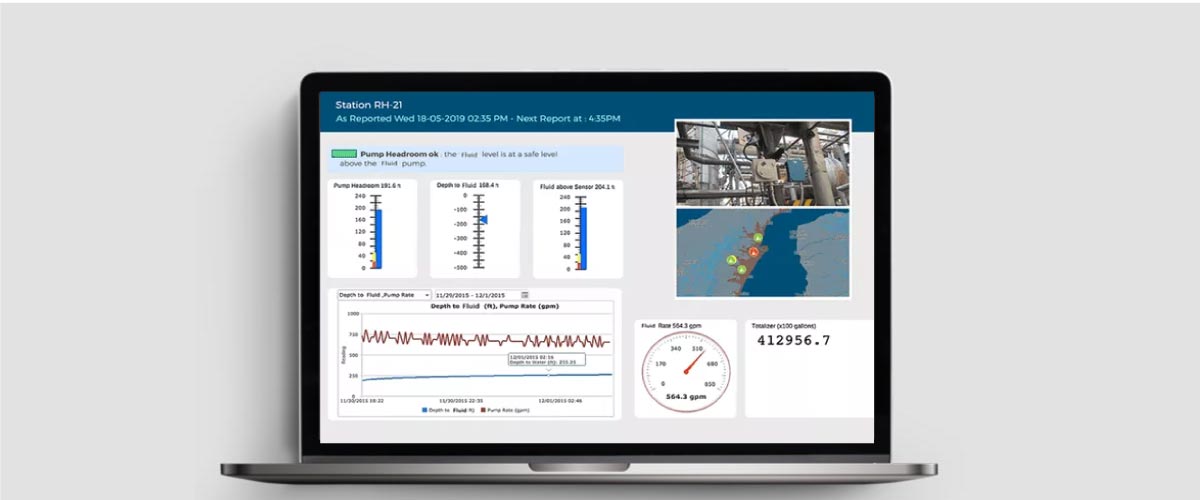

IoT Predictive Maintenance Case Study: IoT-Powered Solution for Fluid Management

A leading manufacturer of fluid control systems faced challenges in effectively monitoring storage tanks and optimizing fluid management.

Challenges:

- Lack of a system to capture and integrate operational data from multiple sensors and devices.

- Inability to handle large volumes and velocity of data impacting bottom-line results.

- Limited visibility of functions across business operations, causing a performance gap.

We analyzed the client’s operations and developed a comprehensive solution. Key components included:

- Predictive analytics mechanism for real-time monitoring of equipment performance and weather conditions.

- Fluid management solution dashboard with liquid level monitoring application.

- Predictive maintenance alerts are triggered by comparing current data with ideal data in the database.

- Unified platform with customized dashboard and five modules for transparent data management.

Benefits:

- Automated validation, sorting, and versioning of data for quality reporting.

- Up to 75% reduction in time spent on routine processes, improving performance.

- 30% cost savings through predictive analytics for early issue detection and maintenance.

- 40% increase in sales revenue with an expanded customer base.

Gain in-depth insights into how this IoT-Powered Solution for Fluid Management with Advanced Data Analytics transformed fluid management processes and optimized operational efficiency in a practical industrial setting.

FAQs

Q: What is the difference between preventive vs. predictive maintenance?

A: Preventive maintenance relies on historical data and is scheduled based on calendar time or asset runtime. Just like a physical check-up can help prevent illness or disease and lengthen your life, preventive maintenance can prevent assets from unexpected equipment failures and extend the functional life of your asset.

Predictive maintenance (PdM) leverages advanced data analytics and predictive analytics to estimate machine reliability and potential asset failures before they occur. Through real-time monitoring and analysis through sensors and machine learning algorithms, predictive maintenance can forecast potential equipment failures and enable technicians to take corrective action. More and more companies are moving to predictive maintenance, where they can use data and analytics to estimate early signs of failure of the equipment and cut down on unplanned downtime.

Q: How are IoT and AI revolutionizing predictive maintenance?

A: Unanticipated machinery failures have resulted in extra costs, time delays, and numerous losses across all industries. IoT and AI together have revolutionized the way industries function by adding intelligence to predictive maintenance and offering the ability of the devices to think for themselves. There is a major shift from preventive maintenance and a centralized cloud intelligence model to a more distributed intelligence model that provides visibility to the imminent failure of any pivotal machinery component. Using IoT and AI in predictive maintenance helps minimize equipment downtime, maintain production schedules, and reduce emergency repairs and lost production time costs.

Q: What criteria can predictive maintenance IoT sensors measure?

A: IoT predictive maintenance sensors can accurately measure temperature, humidity, proximity, fluid levels, and more in real-time. These features make it highly beneficial for almost all types of manufacturing equipment. It is practically the Swiss Army knife of maintenance solutions.

Q: Why use an IIoT predictive maintenance app for your manufacturing needs?

A: IIoT predictive maintenance helps improve the maintenance department’s capabilities and efficiency to unlock significant cost savings. With IIoT, manufacturers can equip pivotal machinery with sensors to constantly monitor key health parameters like vibration and temperature, among others, and report machine status. IIoT-driven predictive maintenance systems use this real-time data collection and analysis to provide insights into equipment performance. Thus, because of IIoT, manufacturers now have unprecedented visibility into their machinery’ performance, allowing them to increase uptime and reduce costs.

Footnotes:

1. https://assets.new.siemens.com/siemens/assets/api/uuid:3d606495-dbe0-43e4-80b1-d04e27ada920/dics-b10153-00-7600truecostofdowntime2022-144.pdf

2. https://www.fda.gov/drugs/drug-shortages/frequently-asked-questions-about-drug-shortages

3. https://ispe.org/about

4. https://www.ttnews.com/sites/default/files/pdfs/TMC-Parts-and-Labor-Costs-Stabilize.pdf

30 Min

30 Min